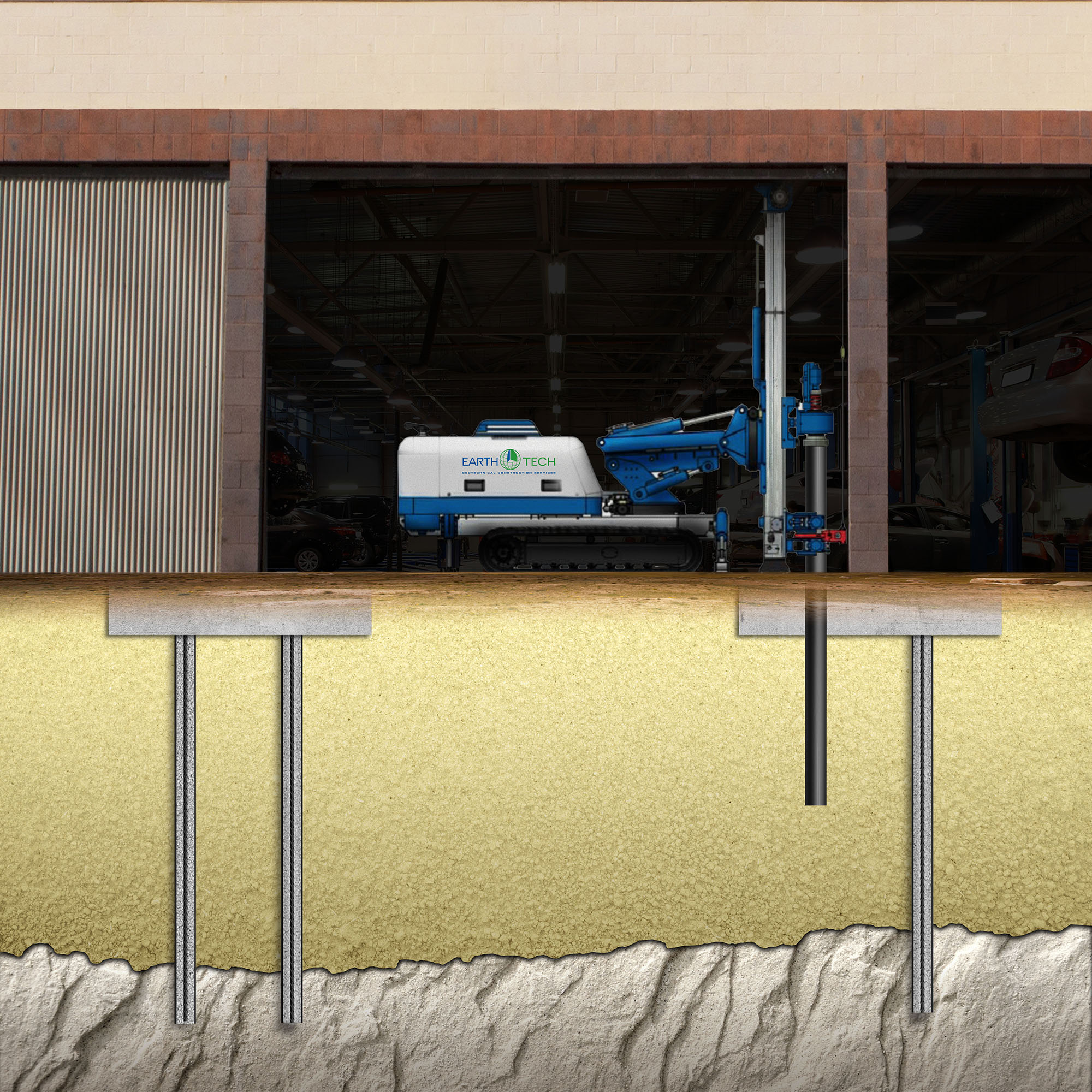

Earth Tech installed Micropiles are three to nine inches drilled in place sectional steel casing or hollow steel rebar piles. Micropiles derive their capacity through a bond zone within a bearing bedrock, usually called the “rock socket”. The diameter and length of the rock socket is designed to achieve the desired capacity of the Micropile. Micropiles can be designed to resist compression, uplift, and lateral forces and are an excellent option when access for conventional piling equipment is limited or not economical.

The “rock socket” is formed by drilling into the bedrock either with the Micropile steel casing/hollow bar or a separate drill string and bit located inside the Micropile casing. Once the rock socket is drilled cement grout is injected locking the steel casing or hollow bar into the rock socket. When inner drill steel and bit is used, it is withdrawn, and a high strength steel rebar is installed through the casing and into the rock socket. The grouted in place steel rebar transfers the load of the steel casing to the rock socket.

When used to underpin (repair) or add support to an existing foundation, Micropile are either installed through or immediately adjacent to the existing foundation.

In each case, once the Micropile has developed its capacity, the Micropile must be structurally connected to the existing foundation. Many connection details are available to fit each unique case.

Applications

-

- To support existing foundations due to additional load, failure or potential undermining of an adjacent excavation

- Restricted access, low head room, interior applications

-

Karst, irregular bearing strata, layered rock

- Foundation underpinning

Construction Advantages

- Versatile product, can be designed to address most structural loadings and geology

- Low noise and construction site impact.

- Equipment can be sized to fit the needs of the site for example larger equipment for production, smaller equipment for specialized needs.