Used for:

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

Advantages

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

- Lorem Ipsum is simply dummy text

What Does Compaction Grouting Entail?

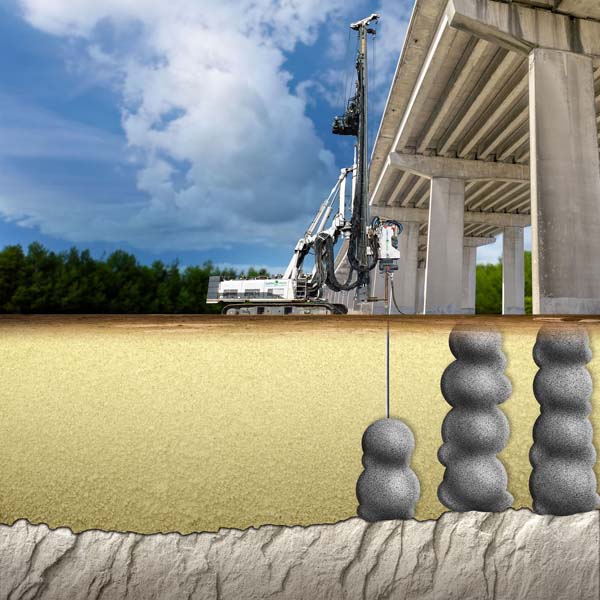

Process

Traditional compaction grouting relies on the constant delivery of a stiff grout material that can be delivered into place under sustained pressures in the order of 500 to 800 psi (3.5 to 5.5 Mpa), Warner2. The grout volume expands as a plastic mass with a discrete interface between the in-situ soil matrix and the grout mass. The grout is accurately placed in localized soil zones, typically 1-2 lineal feet at a time. The point of injection is controlled by raising the tip of the injection pipe into the targeted zone to be improved. It is also vitally important to begin compaction grouting at the top of a strata that is capable of supporting any load that may be transmitted to it as a result of the soil improvement.

Over the past 30+ years of compaction grouting evolution, there have been modifications adapted to grouting design plans, to suite the particular designer. One such significant modification is to combine the benefits of compaction grouting with that of slurry grouting to produce a “Modified Compaction Grouting Program.” This type of program utilizes the homogeneous grout displacement theories with increased mobility to consolidate and strengthen certain soil matrices. This approach has mainly been applied in areas of karst topography.

The 1980 ASCE Grouting Committee defined compaction grout as: “Grout injected with less than 1 in. (25mm) slump. Normally a soil-cement with sufficient silt sizes to provide plasticity together with sufficient sand sizes to develop internal friction. The grout generally does not enter soil pores but remains in a homogeneous mass that gives controlled displacement to compact loose soils, gives controlled displacement for lifting of structures, or both.”

Grouting Operations – Extracting the grout pipe during pumping

This design concept has been used to create a compaction grout “matt” over an extended area by placing grout injection points on a grid over the area with problematic soils. This technique utilizes the physical properties of a compaction grout mix with a slightly higher water:solids ratio to displace soft soils above a stable, but porous limestone strata and fill voids and fissures that have developed as a result of solutioning in a Karst system. In applications such as this where typical specifications for compaction grouting are not met, specifically the slump criteria, it becomes even more important to maintain a grout design mix that achieves the desired objectives.

The grout slump is not directly related to the mobility or pump ability of the grout. Very low slump grouts can be highly mobile, whereas very high slump grouts can be formulated that have essentially no mobility. The principle factors which influence both slump and mobility are the shape and gradation of the sand material, the amount and nature of the fine fraction therein, and the inclusion of lubricating and/or water retention additives, Warner2. The Modified Compaction Grouting technique can effectively be used to limit the flow of water or contamination from upper to lower soil zones or to seal off the top of rock in areas of soil raveling and solutioning.

Compaction Grouting techniques combined with Mini Piles have effectively been used to transfer loads through problematic soil zones to a more competent bearing strata without going to greater depths to encounter rock. This process is typically used in the remediation of lighter structures that have experienced settlement. An attachment to an existing foundation is normally used to integrate the Compaction Grout Pile. Other methods include the use of a longer grout zone reinforced with steel bar in less compressible soils. The reinforced grout column can be extended into an underlying competent soil strata to produce an increased load carrying capacity. It should be noted that a fair degree of controversy exists among engineers & designers over the long term effectiveness of compaction grouted piles. The major concern centers around the bond between the grout and the pipe, the actual end bearing capacity of the pile and the effects of creep.